Plastic Bearing Design Considerations

To select the right plastic bearing for your application, several important design factors must be considered. These are bearing load, shaft speed, operating clearance, shaft material and finish, duty cycle, environment and housing material.

How to Calculate Bearing Load

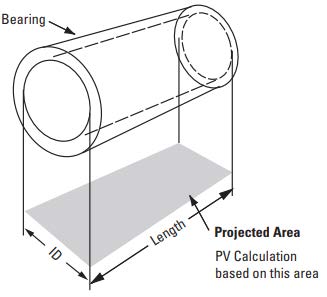

Expressed as pressure (P), is measured in pounds per square inch (PSI). Square inch area is determined by multiplying the bearing’s inside diameter by the bearing length.

Pressure (P) = Load / Projected Area

Shaft Surface Speed or velocity (V), is expressed in feet per minute (FPM).

Surface Velocity (V)= Shaft rpm x Shaft Diameter in Inches x .262

What is PV Value (PV) for Plastic Bearings?

The combined effect of pressure (P) multiplied by velocity (V). PV defines the maximum combination of pressure and speed that a bearing material is capable of withstanding. Operating a bearing more than its PV may result in premature failure. Lubrication will significantly increase the PV rating of a bearing.

PV= Pressure (P) x Surface Velocity (V)

How to Calculate PV Value (PV) for Plastic Bearings

The PV value is a performance measurement that is the product of pressure (psi) and velocity, (surface feet per minute)

PV = Pressure × Surface Velocity

PV = Radial Load (pounds) / Projected Area (in2)

PV = Radial Load (pounds) / Projected Area (in2) × Revolutions Per Minute × Inside Diameter of Bearing (in) × .262

Factors That Impact Bearing PV Rating

Clearance

The single most important factor governing a plastic bearing’s PV performance is the bearing to shaft running clearance. Recommended clearances for all Thomson Nyliner plastic bearings are given by bearing type.

Shaft Hardness and Material

For long service life and optimum bearing performance, the use of carbon steel, case hardened to Rockwell C60, with a surface finish of 16 micro inches Ra, is recommended. Non-ferrous shaft materials, such as aluminum or brass are not recommended for use with the Thomson Nyliner plastic bearings but may be sufficient in certain applications.

Operating Cycles

Although plastic bearings may be operated dry, a few drops of oil added during the breaking-in period can significantly increase operating life. This initial lubrication creates a highly polished bearing surface, which maximizes the low friction characteristics of the bearing.

Housing Material

Housing materials for plastic bearings should possess good heat transfer characteristics to minimize potential bearing overheating.

Load Ratings

For dry operation, a film of lubricant should be present on the bearing surface during the initial break-in period. If for any reason the lubricant is removed, it should be replaced prior to putting the bearing in service. Bearings lubricated with liquids other than oil will operate satisfactorily at load ratings from 50% to 75% of the oil lubricated ratings.

Static-load capabilities are based on the compressive strength of the proprietary Thomson Nyliner Engineering Polymers and indicate the resistance of these materials to continuous heavy-duty, non-rotating loads or to impact loads without permanent deformation. Load ratings are based on continuous operation. For intermittent service, load ratings may be increased up to 100%.